Laser cleaning machines have gained immense popularity due to their ability to transform surface cleaning and preparation in various industries. These advanced machines utilize cutting-edge laser technology to effectively remove contaminants such as rust, paint, and dirt from different surfaces without causing damage to the underlying material.

However, before investing in laser cleaning solutions, it is essential to consider several factors to ensure optimal performance and value. In this article, we will highlight the top laser cleaning machine manufacturers.

Overview

The laser cleaning machine industry is rapidly expanding, driven by increasing demand for sustainable and efficient cleaning solutions. As of 2024, the market was valued at approximately $564 million and is projected to grow to $1.015 billion by 2032, with a compound annual growth rate (CAGR) of 7.20%. This growth is fueled by advancements in laser technology and a shift towards environmentally friendly practices across multiple sectors, including automotive, aerospace, and manufacturing.

Top 10 Laser Cleaning Machine Suppliers

TRUMPF

TRUMPF is a leading global provider of advanced manufacturing solutions, particularly renowned for its expertise in laser technology and machine tools. With a rich history dating back to 1923, TRUMPF has established itself as a pioneer in the development of innovative laser cleaning machines, which are essential for various industrial applications.

Website: www.trumpf.com

Business Type: Manufacturing of laser technology and machine tools

Headquarters: Farmington, Connecticut, USA

Main Markets: North America, Europe, Asia

Establishment Year: 1923

Certificates/Awards: ISO 9001 Certification, Industry 4.0 Certification, multiple innovation awards in manufacturing technology

TRUMPF excels in the laser cleaning machine industry, offering a comprehensive range of advanced solutions, including the TruMark and TruMicro series. These innovative machines leverage state-of-the-art laser technology to efficiently eliminate contaminants like rust, oil, and dirt from various surfaces. The versatile TruMark series is designed for both cleaning and marking applications, catering to sectors such as automotive, aerospace, and electronics. Meanwhile, the TruMicro series features high peak pulse lasers ideal for large-scale cleaning tasks, underscoring TRUMPF’s dedication to innovation and operational efficiency.

With cutting-edge manufacturing facilities located in Farmington and Plymouth, Michigan, TRUMPF meets the needs of both small-scale operations and large industrial applications. The company allocates approximately 10% of its sales revenue to research and development, ensuring its products remain at the forefront of technology. This commitment has led to significant advancements in laser cleaning techniques that not only enhance productivity but also reduce environmental impact.

TRUMPF’s unique value proposition lies in its ability to deliver high-quality, reliable laser cleaning solutions tailored to client needs. By focusing on innovation, exceptional customer support, and competitive pricing, TRUMPF continues to lead the market in laser technology and machine tools, empowering manufacturers to achieve greater efficiency and precision in their operations.

Baison Laser

Baison Laser is a leading player in the laser technology industry, specializing in the development and manufacturing of advanced laser cleaning machines. With a commitment to innovation and quality, Baison has established itself as a trusted supplier for various sectors requiring precision cleaning solutions.

Website: baisonlaser.com

Business Type: Manufacturer of laser cleaning machines and related laser technology solutions

Headquarters: Foshan, Guangdong, China

Main Markets: Global markets including North America, Europe, Asia, and Australia

Establishment Year: 2004

Certificates/Awards: ISO 9001 Certification, CE Certification, numerous patents in laser technology

Baison Laser operates advanced production facilities spanning over 100,000 square meters in Foshan, China, with an annual output capacity exceeding 3,000 units of fiber laser cleaning machines. This impressive capability is backed by a dedicated workforce of over 500 professionals committed to innovation and excellence. With more than 240 patents in laser technology, Baison Laser is at the forefront of developing high-performance cleaning solutions tailored for industries such as automotive, aerospace, oil and gas, and manufacturing.

The company’s product lineup features state-of-the-art pulse laser cleaning systems that efficiently eliminate rust, paint, and contaminants without damaging surfaces. Utilizing non-contact methods, these machines are not only safe for operators but also environmentally friendly. Baison Laser’s technology enhances cleaning efficiency while significantly reducing operational costs compared to traditional techniques like abrasive blasting and chemical cleaning.

Baison Laser distinguishes itself through comprehensive customer support throughout the buying journey—from design and manufacturing to installation and after-sales service. The company’s commitment to quality assurance and competitive pricing positions it as a preferred partner for businesses seeking reliable laser cleaning solutions. With a strong market presence and a focus on innovation, Baison Laser continues to set benchmarks in the laser technology industry.

IPG Photonics

IPG Photonics Corporation stands as a global leader in the development and manufacturing of high-power fiber lasers and amplifiers, with a strong emphasis on innovative laser cleaning solutions. The company has established itself as a key player in the laser technology industry, providing advanced solutions that cater to various sectors including automotive, aerospace, medical, and industrial applications.

Website: www.ipgphotonics.com

Business Type: Manufacturer and supplier of fiber lasers and laser systems

Headquarters: Marlborough, Massachusetts, USA

Main Markets: North America, Europe, Asia

Establishment Year: 1990

Certificates/Awards: Recognized as a 2024 Innovators Awards honoree by Laser Focus World for advancements in laser technology

IPG Photonics is a global leader in advanced laser technology, specializing in high-power fiber lasers and innovative laser cleaning solutions. With manufacturing facilities in the United States, Germany, Russia, and Italy, IPG maintains a vertically integrated production process that guarantees superior quality and cutting-edge innovation in laser applications.

The company’s extensive product portfolio includes fiber lasers, optical delivery cables, and beam switches, catering to diverse industries such as automotive, aerospace, and medical. Notably, the acquisition of cleanLaser has strengthened its offerings in the laser cleaning market, providing eco-friendly and efficient cleaning solutions that eliminate the need for harsh chemicals or abrasive materials.

IPG’s commitment to technological advancement is highlighted by its LightWELD system, which incorporates automated cobot technology for precision welding and cleaning tasks. This system enhances production efficiency while reducing operational costs by minimizing waste. Recognized for their energy efficiency and low total cost of ownership, IPG’s fiber lasers are ideal for manufacturers seeking to boost productivity while adhering to environmental standards.

Overall, IPG Photonics delivers exceptional value through its state-of-the-art technologies and dedication to sustainability. By offering reliable, high-performance laser solutions tailored to meet the evolving needs of various sectors, IPG positions itself as a preferred partner for businesses aiming for innovation and operational excellence.

Coherent

Coherent is a leading global provider of laser technology solutions, renowned for its innovative approach and extensive expertise in the field of laser cleaning machines. With a strong commitment to quality and sustainability, Coherent has established itself as a key player in the laser cleaning industry, offering advanced solutions that cater to a diverse range of applications across various sectors.

Website: coherent.com

Business Type: Manufacturer of laser systems and components, specializing in laser cleaning technologies.

Headquarters: Saxonburg, Pennsylvania, USA

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1971

Certificates/Awards: ISO 9001 Certification, various industry awards for innovation and sustainability.

Coherent specializes in laser cleaning technology, providing high-energy pulse systems for effective surface cleaning, rust removal, and paint stripping across diverse materials. These advanced laser cleaning machines are particularly sought after in the aerospace, automotive, and manufacturing sectors due to their non-abrasive nature, which preserves the integrity of underlying surfaces. Coherent’s state-of-the-art production facilities uphold stringent quality standards, ensuring that every machine meets the rigorous demands of a global clientele.

The company is dedicated to continuous innovation in laser cleaning solutions, utilizing both pulsed and continuous wave laser technologies to create tailored systems that address specific customer needs. Coherent also offers comprehensive support services, including training and after-sales assistance, reinforcing its commitment to exceptional customer satisfaction.

Coherent’s unique value proposition lies in its blend of cutting-edge technology and deep customer insight. By offering customizable options and a wide range of products, the company ensures clients find optimal solutions for their cleaning challenges. This focus on innovation and customer-centric service solidifies Coherent’s position as a trusted partner in the evolving landscape of industrial cleaning solutions.

Laserax

Laserax is a prominent player in the laser technology industry, specializing in advanced laser solutions for various applications, including cleaning, marking, texturing, and welding. Established in 2010, the company has quickly gained recognition for its innovative approach and commitment to quality in laser cleaning technology.

Website: www.laserax.com

Business Type: Manufacturer of laser cleaning machines and systems

Headquarters: Quebec City, Quebec, Canada

Main Markets: North America, Europe, Asia

Establishment Year: 2010

Certificates/Awards: ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management)

Laserax excels in the laser cleaning technology sector, offering a diverse range of high-performance laser systems tailored for industries such as automotive, battery production, and metalworking. With a strong commitment to sustainability, Laserax’s solutions enhance operational efficiency while minimizing environmental impact through eco-friendly practices.

The company boasts an impressive portfolio of patented technologies, including advanced fiber laser cleaning machines that effectively remove rust, paint, and contaminants without damaging underlying surfaces. Additionally, Laserax provides automated solutions that seamlessly integrate into existing production lines, optimizing workflows and ensuring superior surface preparation.

Laserax’s unique value proposition lies in its ability to deliver customized laser cleaning solutions that meet specific industrial needs. By merging cutting-edge technology with exceptional customer support, the company empowers clients to achieve outstanding results in their manufacturing processes. This dedication to quality and innovation solidifies Laserax’s position as a leader among laser cleaning machine suppliers.

Laser Photonics

Laser Photonics is a prominent player in the industrial laser technology sector, specializing in advanced laser cleaning solutions. Established in 1987, the company has built a reputation for delivering innovative and eco-friendly laser systems that cater to a wide range of applications across various industries.

Website: www.laserphotonics.com

Business Type: Manufacturer of industrial laser cleaning, cutting, engraving, and marking systems.

Headquarters: Orlando, Florida, USA

Main Markets: North America, Europe, Asia-Pacific

Establishment Year: 1987

Certificates/Awards: Green Manufacturing Award, multiple industry certifications for safety and quality.

Laser Photonics is a leading manufacturer in the laser cleaning industry, renowned for its innovative and eco-friendly cleaning solutions. The company specializes in a wide range of laser cleaning machines, including handheld models and advanced automated systems under its CleanTech brand. By utilizing cutting-edge technology, Laser Photonics effectively removes contaminants without the need for harsh chemicals or abrasives, making it an ideal choice for various industrial applications.

The state-of-the-art manufacturing facility in Orlando, Florida, enables Laser Photonics to produce high-quality laser systems tailored to meet diverse client needs across sectors such as aerospace, automotive, and energy. With a robust annual output capacity, the company caters to both small businesses and Fortune 500 clients, ensuring efficient delivery of customized solutions. Their commitment to quality and competitive pricing positions Laser Photonics as a trusted partner in the laser technology market.

By choosing Laser Photonics, clients benefit from reliable cleaning solutions that enhance productivity while adhering to stringent environmental standards. The company’s dedication to ongoing innovation ensures it remains at the forefront of the laser cleaning sector, providing unparalleled value through advanced technology and exceptional service.

CleanLASER

CleanLASER is a prominent player in the laser cleaning industry, recognized for its innovative and high-precision laser cleaning solutions. Established in 1997, the company has built a reputation as a leader in expanding the applications of laser technology for industrial cleaning, serving various sectors globally.

Website: www.cleanlaser.de

Business Type: Manufacturer of laser cleaning systems

Headquarters: Herzogenrath, North Rhine-Westphalia, Germany

Main Markets: Europe, North America, Asia, and other international markets

Establishment Year: 1997

Certificates/Awards: ISO 9001, ISO 14001, CE certification

CleanLASER specializes in laser cleaning technology, offering both portable and stationary systems designed for diverse applications such as rust removal, paint stripping, and surface preparation. With an impressive annual output of approximately $30 million and a global footprint of around 2,000 installed systems, CleanLASER is a trusted name in the industrial sector. Their product range includes fiber-coupled laser systems with power ratings from 20 to 1000 watts, ensuring tailored solutions for various customer needs.

The company is committed to quality and innovation, providing advanced laser systems that excel in efficiency and versatility. These systems are suitable for a range of environments, from handheld operations to fully automated robotic work cells. CleanLASER stands out with its eco-friendly approach, eliminating the need for chemical solvents or abrasives while significantly reducing waste. This commitment to sustainability enhances operational efficiency and aligns with global trends towards greener industrial practices.

Overall, CleanLASER’s value proposition lies in delivering high-performance laser cleaning solutions that combine precision with cost-effectiveness. Their ongoing investment in research and development keeps them at the forefront of technological advancements, offering clients innovative solutions that boost productivity and lower operational costs. By prioritizing both performance and sustainability, CleanLASER positions itself as a leader in the laser cleaning industry.

SCANLAB

SCANLAB GmbH is a renowned leader in the field of laser technology, specializing in the design and manufacturing of advanced scanning solutions for a variety of industrial applications. With a commitment to innovation and quality, SCANLAB has established itself as a pivotal player in the laser cleaning machine sector, providing state-of-the-art products that enhance efficiency and precision in laser processing.

Website: www.scanlab.de

Business Type: Manufacturer of laser scanning systems and galvanometer scanners

Headquarters: Puchheim, Bavaria, Germany

Main Markets: Global markets including Europe, North America, Asia-Pacific, and various sectors such as electronics, food and beverage, biotech, and medical technology.

Establishment Year: 1990

Certificates/Awards: ISO 9001 Certification; numerous industry accolades for innovation and technology leadership.

SCANLAB is a leading manufacturer in the laser technology sector, renowned for its high-performance laser scanning systems and advanced cleaning solutions. With a robust annual output of over 40,000 units, SCANLAB operates from its headquarters in Puchheim, Germany, employing more than 400 skilled professionals dedicated to innovation and customer satisfaction. The company’s extensive product line includes galvanometer scanners, scan heads, control electronics, and specialized software designed for various industrial applications, including eco-friendly laser cleaning technologies that provide sustainable alternatives to traditional methods.

The strength of SCANLAB lies in its commitment to quality and tailored solutions. By collaborating closely with clients, SCANLAB develops customized systems that address specific operational needs. Their ongoing research and development efforts focus on enhancing laser processing techniques, leading to innovations such as the Scanmotion Control system and the Excelliscan 30 Array scan head. These advancements optimize laser applications across multiple industries, ensuring efficiency and precision in material processing.

Overall, SCANLAB’s value proposition is centered around delivering reliable, high-quality laser scanning solutions that drive operational efficiency while emphasizing sustainability and innovation. As a trusted partner in the laser technology landscape, SCANLAB continues to set industry standards and adapt to the evolving demands of its global clientele.

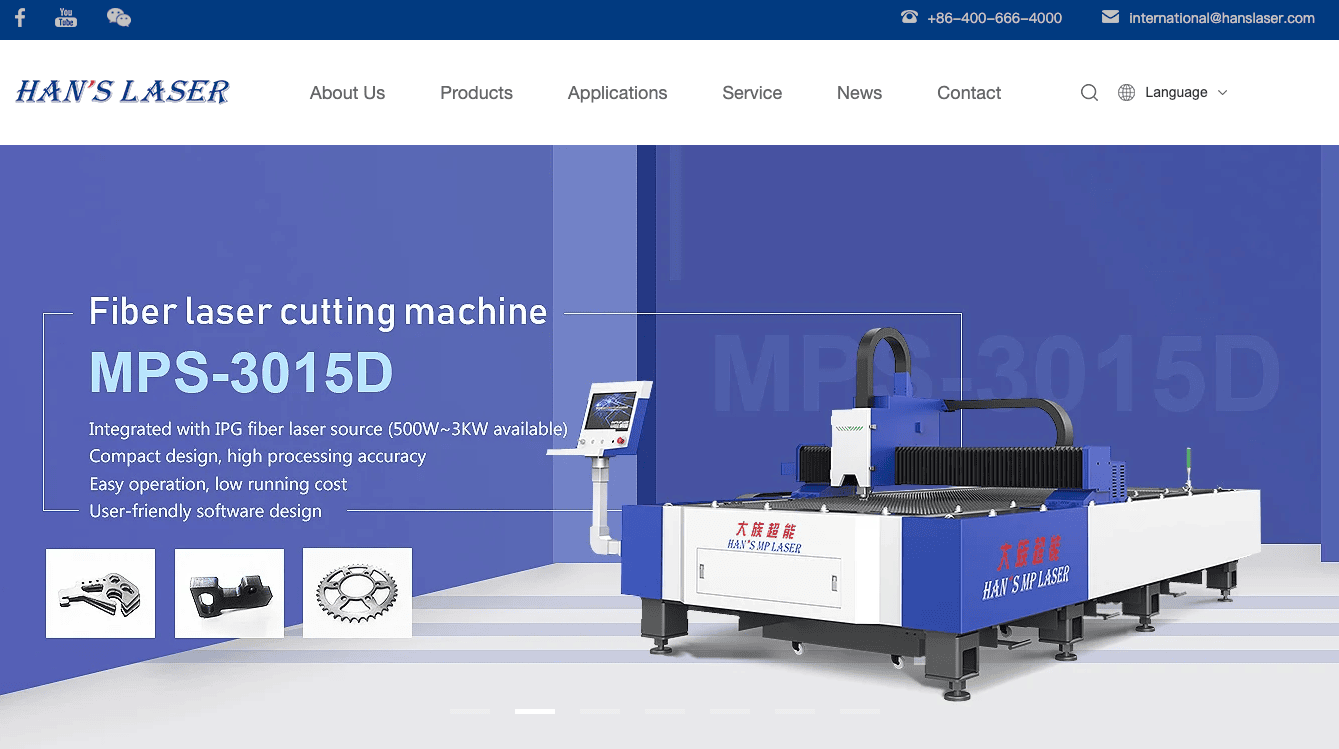

Han’s Laser Technology

Han’s Laser Technology Industry Group Co., Ltd. is a leading manufacturer in the laser equipment sector, recognized as a flagship of the Chinese national laser industry and one of the most prominent laser technology providers globally. Established in 1996, the company has made significant strides in innovation and market presence, becoming a trusted supplier for various industrial applications.

Website: hanslaser.net

Business Type: Manufacturing and sales of laser processing equipment, including laser cleaning machines, laser cutting machines, and laser welding machines.

Headquarters: Shenzhen, Guangdong, China

Main Markets: Global markets with a focus on Asia, North America, and Europe.

Establishment Year: 1996

Certificates/Awards: ISO9001, ISO14001, CE certifications; recognized as a “Top Ten Industrial Robot Enterprises”; multiple awards for technological innovation.

Han’s Laser Technology offers a diverse range of over 200 laser machine models tailored for various industries, including electronics, automotive, aerospace, and medical devices. Their advanced laser cleaning systems are specifically designed to efficiently eliminate contaminants such as rust, paint, and dirt from surfaces. Committed to quality and reliability, Han’s Laser adheres to strict international manufacturing standards, achieving an impressive annual revenue exceeding $2.5 billion with a skilled workforce of over 850 employees.

The company’s dedication to research and development is reflected in its portfolio of over 300 patents and pioneering technologies in the laser cleaning sector. Notable innovations include advancements in fiber laser systems that enhance cleaning efficiency and precision. By integrating cutting-edge automation and intelligent manufacturing practices, Han’s Laser solidifies its status as a leader in the industry.

Han’s Laser Technology distinguishes itself through its comprehensive product offerings, unwavering commitment to quality assurance, and ongoing innovation in laser technology. Their ability to deliver high-performance solutions at competitive prices positions them as the preferred partner for businesses seeking effective laser processing equipment.

Dapeng Laser Technology Co., Ltd.

Shenzhen Dapeng Laser Technology Co., Ltd. is a leading manufacturer and supplier in the laser equipment industry, specializing in advanced laser cleaning technologies. With a commitment to quality and innovation, Dapeng Laser has established itself as a trusted partner for businesses seeking efficient and eco-friendly cleaning solutions.

Website: www.dapeng-laser.com

Business Type: Manufacturer of laser cleaning machines and other laser equipment

Headquarters: Shenzhen, Guangdong, China

Main Markets: Asia, Europe, North America

Establishment Year: 2011

Certificates/Awards: ISO 9001:2015, CE Certification, SGS Certification

Dapeng Laser Technology Co., Ltd. is a premier manufacturer specializing in laser cleaning systems tailored for rust removal, paint stripping, and surface preparation. With over 30,000 square meters of production facilities across China and a skilled workforce of more than 450 employees, Dapeng Laser ensures high production capacity and customized solutions for various industrial applications.

The company offers a diverse range of handheld and portable laser cleaning devices utilizing advanced fiber laser technology. These machines are highly effective for applications in automotive maintenance, aerospace component cleaning, and mold restoration. Dapeng’s dedication to innovation is evident in its continuous technological upgrades, positioning its products at the forefront of the laser cleaning industry.

Dapeng Laser Technology Co., Ltd. emphasizes a customer-centric approach, providing comprehensive pre-sale, in-sale, and after-sale services. By delivering high-quality products at competitive prices, the company enhances operational efficiency for clients while fostering long-term partnerships based on trust and reliability. This commitment to excellence makes Dapeng a leading choice among laser cleaning machine suppliers globally.

Comparison of Laser Cleaning Machine Suppliers

| Supplier | Key Features | Price Range | Specialties |

|---|---|---|---|

| TRUMPF | High-performance systems | Premium | Industrial applications |

| Baison Laser | Portable machines | Competitive | OEM/ODM services |

| IPG Photonics | Fiber lasers | Mid-High | Medical & industrial sectors |

| Coherent | Advanced technologies | Premium | Diverse applications |

| Laserax | High-efficiency solutions | Mid-High | Industrial use |

| Laser Photonics | Versatile product range | Mid | Handheld & heavy-duty |

| CleanLASER | Precision cleaning | Mid-High | Specialized applications |

| SCANLAB | Scanning technology | Varies | Enhancements for existing tech |

| Han’s Laser | Comprehensive solutions | Competitive | Broad industry focus |

| Dapeng Laser | Customizable options | Varies | High-quality performance |

What is a Laser Cleaning Machine?

Laser cleaning machines utilize advanced laser technology to effectively remove contaminants from various surfaces without causing damage. This innovative method has gained traction across multiple industries due to its efficiency, precision, and eco-friendly nature. Understanding the functionality and applications of laser cleaning machines is crucial for businesses seeking effective and sustainable cleaning solutions.

Definition of a Laser Cleaning Machine

A laser cleaning machine is an industrial tool that employs focused laser beams to eliminate unwanted materials such as rust, paint, grease, and other contaminants from surfaces. By directing high-energy laser pulses at a target, the contaminants absorb energy, leading to their evaporation or removal without harming the underlying material. This non-contact method preserves the integrity of delicate components while being robust enough for industrial applications.

How a Laser Cleaning Machine Works

The operation of a laser cleaning machine involves several key steps:

- Laser Generation: The machine produces a high-energy laser beam using a fiber or CO2 laser source.

- Focusing the Beam: The optical system focuses this beam onto a small area of the surface, creating a concentrated spot.

- Material Interaction: When the laser beam strikes the surface, contaminants absorb the energy, causing rapid thermal expansion and vaporization through a process known as laser ablation.

- Cleaning Process: The machine moves the focused beam across the surface in a controlled manner, effectively removing contaminants layer by layer until the desired cleanliness is achieved.

- Control Systems: Modern machines feature advanced control systems that allow operators to adjust parameters such as power, pulse frequency, and scanning speed for optimal cleaning performance across different materials and contaminant types.

Benefits and Uses of Laser Cleaning Machines

Laser cleaning machines provide numerous advantages over traditional methods:

- Eco-Friendly: They eliminate the need for chemicals or abrasives, significantly reducing environmental impact.

- Precision Cleaning: Lasers can selectively target contaminants without damaging the underlying surface, making them ideal for sensitive applications.

- Cost-Effective: While initial investment costs may be higher, operational costs are low due to minimal consumables and reduced labor time.

- Versatile Applications: Laser cleaning is effective for various tasks including:

- Rust removal from metal surfaces

- Paint stripping for restoration projects

- Surface preparation before welding or coating

- Cleaning molds and tools in manufacturing processes.

Limitations and Considerations

Despite their effectiveness, there are limitations to consider:

- Initial Cost: The upfront investment can be significant compared to traditional methods.

- Material Compatibility: Not all materials are suitable for laser cleaning; some may require specific settings or may not respond well.

- Training Required: Operators need training to effectively use and maintain laser cleaning machines.

- Safety Precautions: Proper safety measures must be implemented due to the high-intensity lasers involved in the process.

Practical Tips for Using Laser Cleaning Machines

To maximize effectiveness, consider these tips:

- Understand Your Needs: Clearly define what you need to clean—identify the type of contaminants and materials involved.

- Select Appropriate Settings: Adjust power levels, pulse frequency, and scanning speed based on specific applications and material types.

- Regular Maintenance: Keep the machine well-maintained to ensure optimal performance and longevity.

- Safety First: Always wear appropriate protective gear and follow safety protocols during operation.

Laser cleaning machines offer innovative solutions for various industrial cleaning challenges. Their ability to efficiently remove contaminants while preserving material integrity makes them invaluable in modern manufacturing processes. As industries increasingly seek sustainable cleaning methods, understanding how these machines work will empower businesses to make informed decisions about their cleaning technologies. For further exploration on related topics such as comparisons with traditional cleaning methods or advancements in laser technology, consider seeking additional resources or engaging in industry discussions.

Conclusion

The demand for laser cleaning machines continues to grow as industries seek more efficient and sustainable methods of surface preparation. The suppliers listed above represent some of the best options available as of 2025, each offering unique advantages tailored to different needs within the manufacturing sector. As a leading manufacturer ourselves, we are committed to delivering high-quality solutions that meet the evolving demands of our customers while maintaining excellence in service and support.